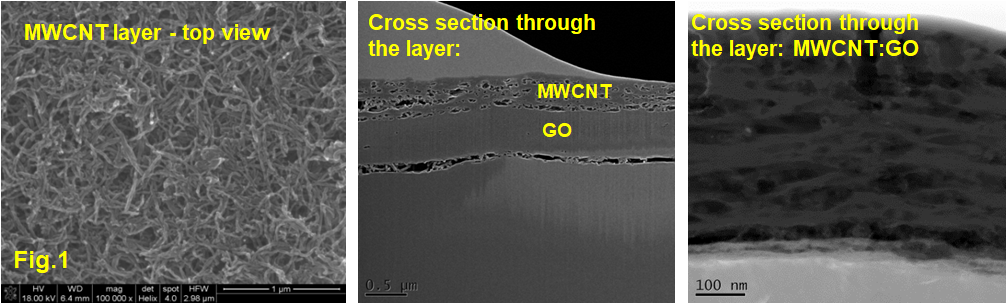

Research carried out in the team focuses on synthetic carbon materials, i.e. materials that are formed by thermal treatment or pyrolysis of organic precursors, both solid, liquid and gaseous. These processes result in nanomaterial-scale materials such as carbon nanotubes (CNTs), carbon nanofibers (CNFs), as well as carbon fibers (CFs), pyrolytic or DLC-type layers, activated carbons, or carbon composites and nanocomposites. In the area of interest of our group are basically all the above-mentioned types of carbons, with a special focus on carbon nanomaterials including CNTs and their modification, the aim of which is to impart the desired functional properties. Thanks to the processes of diversified chemical functionalization, we open the way for many potential applications, both in the field of industry or electronics, as well as to produce advanced biomedical solutions. Our areas of interest include, among others, issues in the field of tissue engineering, enabling the regeneration of tissues with low regenerative potential, such as bone, cartilage, nerve, or muscle tissue. In this area, nanomaterials with different degrees and types of functionalization, nanomaterials in the form of layers on metallic substrates (Fig.1),

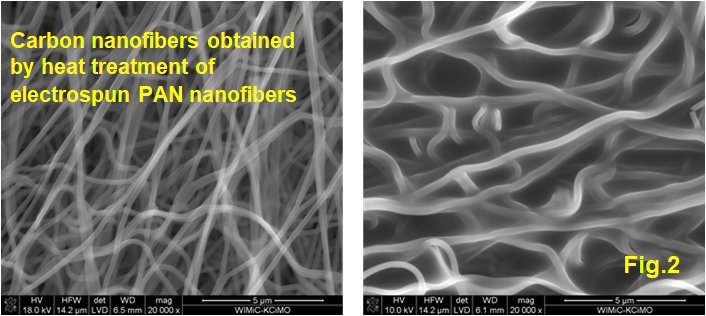

as well as three-dimensional systems obtained by 3D printing, bioprinting and electrospinning (Fig.2).

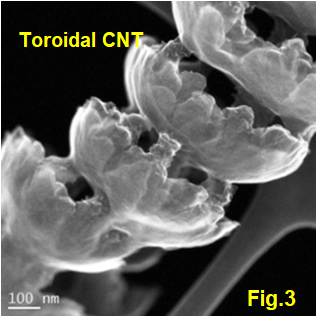

We are also interested in the work carried out towards the synthesis of new carbon nanostructures, such as toroidal carbon nanotubes (Fig. 3), graphene and carbon nanotubes with the desired physicochemical properties, obtained from the decomposition of polycyclic aromatic hydrocarbons (PAHs).

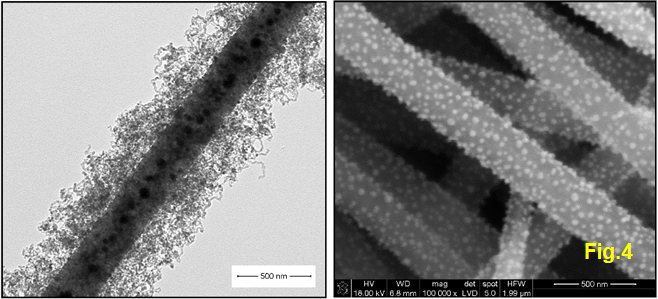

As part of the group’s work, research is focused on the preparation and new applications of hybrid nanocomposites based on electrospun carbon nanofibers, including the so-called branched nanofibers and nanofibers with immobilized metallic nanoparticles (Fig. 4). Branched nanofibers, also known as hierarchical nanofibers, are a new type of nanocomposite materials whose main characteristic is their hierarchical structure, formed by carbon nanotubes growing radially directly from subnanometric core nanofibers. This type of morphology results in a significant increase in the specific surface area of nanofibers, density of catalytically active sorption centers, improved electrical conductivity and sensing capabilities, or a change in the wetting mechanism, etc. Moreover, immobilization of metallic nanoparticles on carbon carriers is a method to obtain advanced electrochemical interfaces characterized by high chemical stability and resistance to leaching while maintaining excellent activity and electrical conductivity. Potential application areas for these materials include the fields of energy conversion and storage, analytical chemistry, nanoelectronics, biomaterials, filtration, etc.

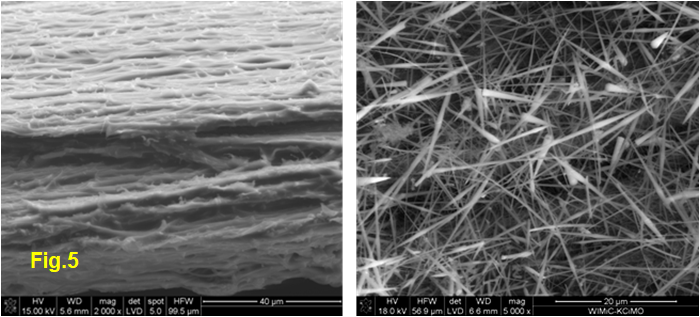

Another area of our research are ceramic nanocomposites modified by carbon nano- and microfibers, in which the ceramic phase was formed as a result of the thermal transformation of a polymer containing silicon. The ability to control the phase proportion of preceramics relative to the carbon phase, and to the optimization of the thermal processing parameters of these materials, affects the morphology of the resulting ceramic phase, allowing to obtain SiC in the form of layers, as well as nanowires or nanoneedles (Fig.5). Polysiloxane-derived ceramic matrix composites and nanocomposites (CMCs or CMNCs) with carbon phases represent an interesting development for materials with applications in modern electronics as multifunctional nanocomposites, electrochemical power sources for a new generation of lithium-ion batteries, flexible electrodes, fuel cells and supercapacitors, as well as an antimicrobial material.

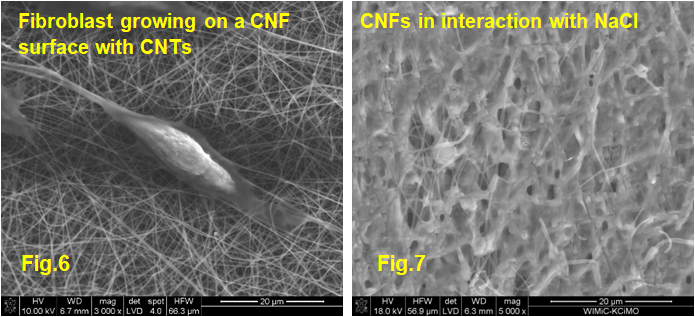

Our research work also includes chemical modification of carbon nanofibers with non-directional and directional fiber positions. The main areas of potential use for these materials are substrates for tissue regeneration (Fig. 6), as well as membranes for purification, or water desalination (Fig.7). We modify as well as commercially available materials, as those we produce by carbonizing fibrous mats made by electrospinning of carbon precursors, such as polyacrylonitrile (PAN).

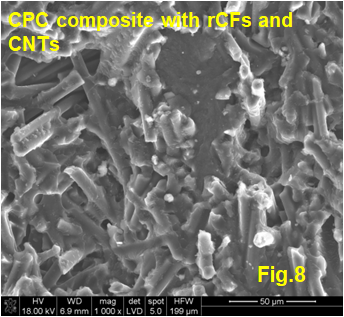

Another important field we are researching is the preparation of conductive polymer composite materials (CPCs). Using the proper type of filler and its appropriate dispersion in the matrix, it is possible to exceed the percolation threshold and obtain a highly electrically conductive material. In our case, the modifying phase consists of recycled carbon fibers (rCF), graphite and/or nanometric phases in the form of CNTs, graphene or various types of carbon black (Fig.8). The presence of the recyclate in the form of carbon fibers in an epoxy resin matrix significantly modifies the electrical, mechanical and thermal properties of the resulting composites. The addition of a secondary nanofiller in the form of CNTs to such a system makes it possible to improve the physical contact between individual microfibers and shorten the conduction path, which are the main reasons for the significant improvement in the conductivity of the materials. These results indicate that rCFs can be used as fillers for CPCs and the addition of a small amount of carbon nanomaterials allows the formation of the hybrid composites with potential applications in electromagnetic shielding, fuel cells, sensors and as a conductive binder.

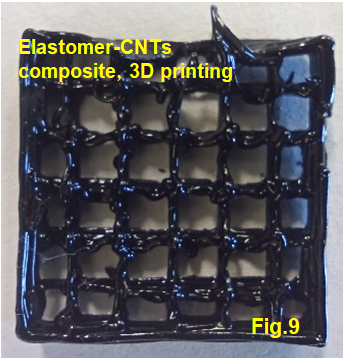

For elastomers, the addition of a small amount of CNTs into the matrix made it possible to obtain a flexible electrically conductive material that can be processed using 3D printing techniques (Fig. 9). Such materials can be used to print precise and flexible electroconductive systems, which can be applied in medicine as sensors for biomedical signals. In addition, modification with carbon nanomaterials of biomaterials (including biopolymers) allows obtaining electrically conductive substrates for cell and tissue culture in vitro.

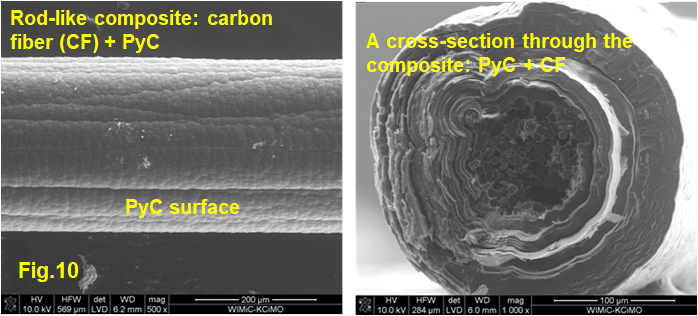

Our new area of interest is the synthesis of carbon-carbon (C-C) composites where one of the carbon phases is carbon fibers/nanofibers and the other is pyrocarbon (PyC). Synthesis of C-C composites based on PyC, obtained by CVD or chemical vapor phase infiltration (CVI), has been known in the literature for many years. However, the main disadvantage of mentioned processes is the long synthesis time of PyC, taking up to tens of hours. Thanks to a new device for synthesizing PyC by resistance [fiber] heating and CVD, it is possible to obtain PyC on the surface and volume of fibrous composites in a few minutes (Fig. 10). These systems, in the form of rods with dimensions of several hundred micrometers, will be a type of electrodes dedicated to deep brain stimulation in the treatment of neurodegenerative diseases. The system for synthesizing PyC also offers the possibility of obtaining C-C composites for technical applications, as well as opening up the opportunity to develop new materials, including nanomaterials, and run advanced experimental work in this area.

A further interesting group of materials we produce are carbon-carbon (C-C) composites and carbon granular (particulate) composites, on which we are collaborating with industry, i.e. Tokai Cobex Polska and SGL Carbon. C-C composites are a class of highly specialized synthetic carbon composites, characterized by a wide range of unique physical and chemical properties. Nowadays, they are most widely used in such fields as aerospace engineering, automotive, biomaterials, high-energy physics, semiconductor technology, refractory materials, etc. On the other hand, the most important applications of granular composites are the production of carbon and graphite electrodes for the aluminum, silicon and steel industries. Today, these materials account for about half of the world’s industrial carbon production. We also undertake research into the properties of carbon fiber-reinforced composite materials, phase, structural and microstructural analysis of carbon nanomaterials and many more. Most of these are driven by the demand of our partners and the market. Research work is realized at the University but also outside the University – in interuniversity research teams of an interdisciplinary nature and in cooperation with industry.